Conveyor Systems are mechanical devices or assemblies that transport material with minimal effort. While there are many different kinds of conveyor systems, they usually consist of a frame that supports either rollers, wheels, or a belt, upon which materials move from one place to another. They may be powered by a motor, by gravity, or manually. These material handling systems come in many different varieties to suit the different products or materials that need to be transported.

Industrial Conveyors

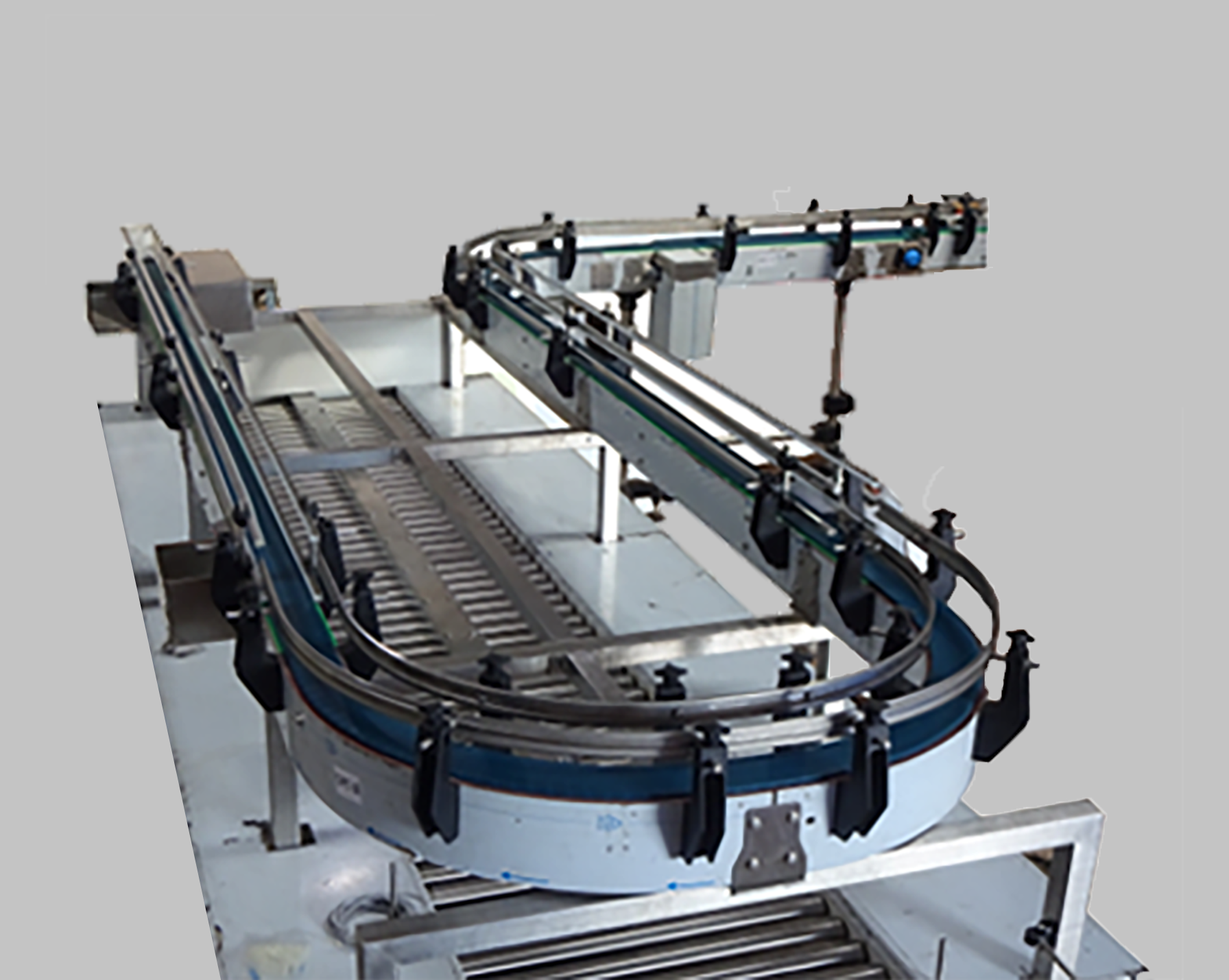

Roller conveyors are optimized for transporting a wide variety of crates, boxes, polybags and pallets. A version in freewheel or electrically controlled roller conveyor gives you flexibility in layout, application and budget. This way you can efficiently use this type of conveyor in every phase of your product flow: order picking, processing, packaging, transport, etc. The modular construction offers you further options in future modifications and / or extensions.

Spiral Conveyor System offered feature latest technology support and provide for even and smooth conveying of goods from floor to floor and in bottom upwards working position or from top floor to ground as per the specific processing needs of the customers. These belts of these conveyors allow transportation of loose materials in lumps/pieces form as well as handle the demands of efficiently bridging medium/long distances and for meeting requirements of transporting heavy material.

A gravity roller conveyor lets a product move on rollers using the force of gravity to move the load. Gravity conveyors are one of the simplest and affordable types of material handling systems. They work by allowing the product to roll along the upper surface.

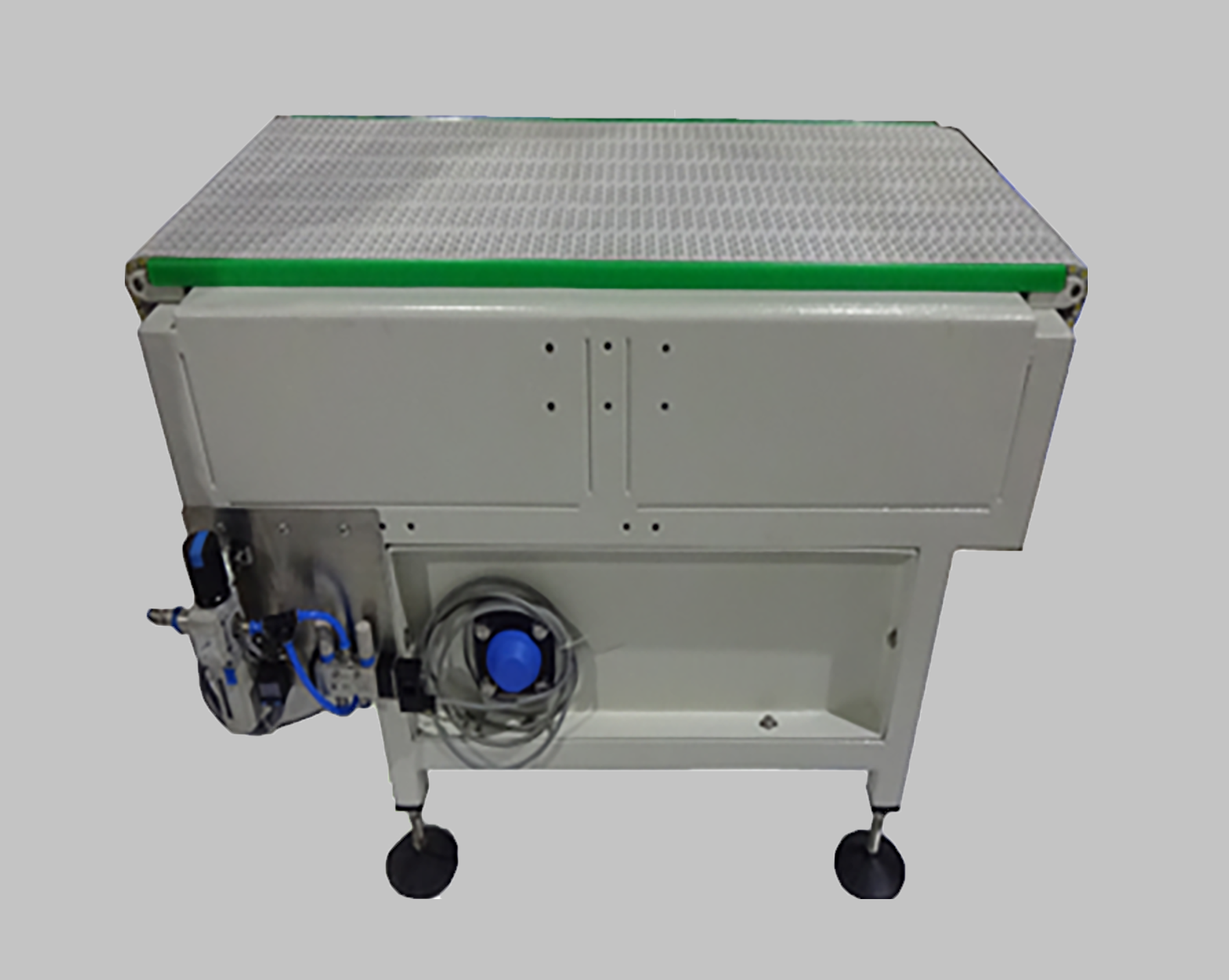

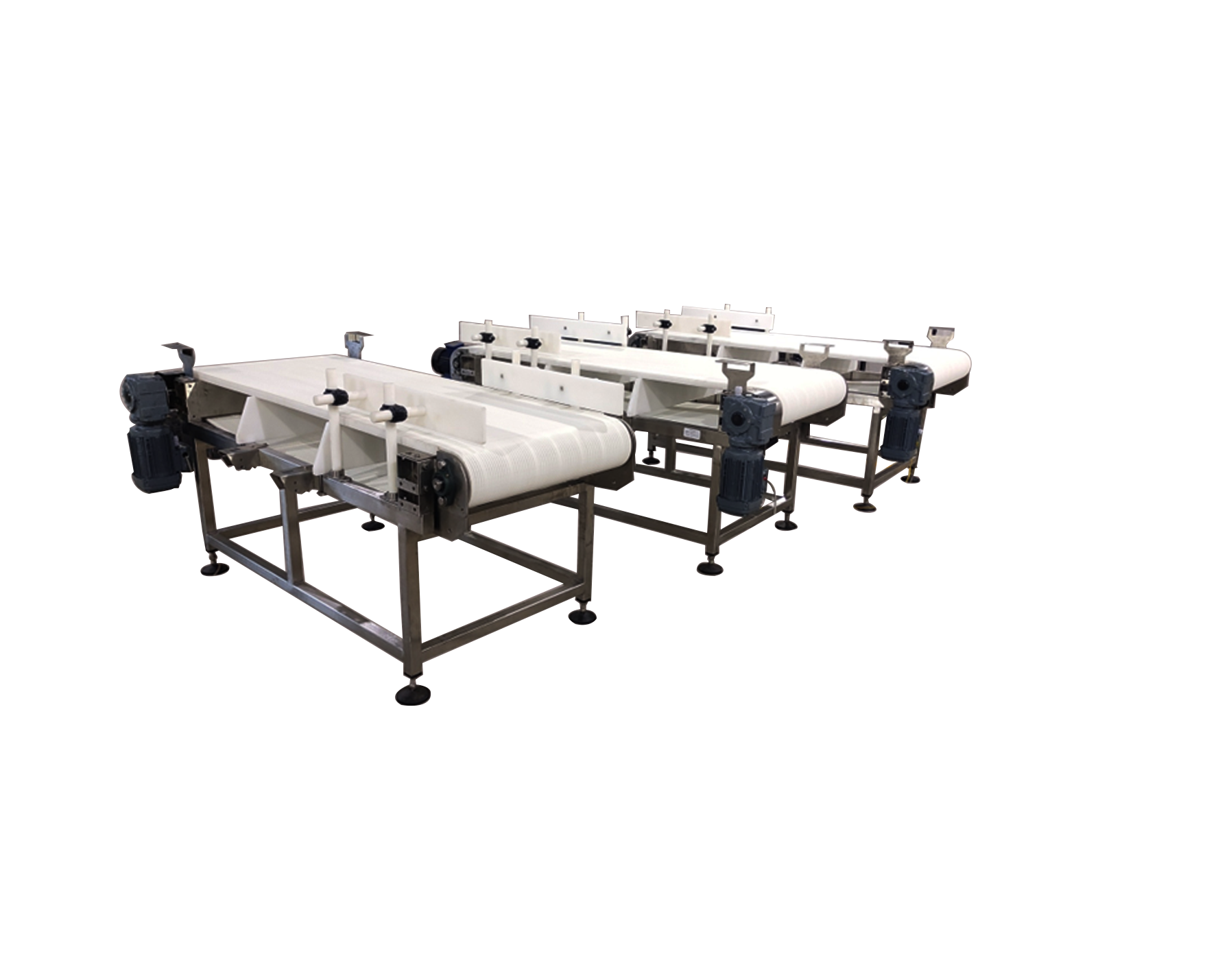

Flat Belt Conveyors are Belt Conveyors in which the carrying run is supported by flat-belt idlers or pulleys. To align a flat belt conveyor simply adjust the tail end pulley or the idler pulley, it is provided with adjuster bolt to adjust it in order to align the conveyor.

Flat Belt Conveyors are Belt Conveyors in which the carrying run is supported by flat-belt idlers or pulleys. To align a flat belt conveyor simply adjust the tail end pulley or the idler pulley, it is provided with adjuster bolt to adjust it in order to align the conveyor.

Flat Belt Conveyors are Belt Conveyors in which the carrying run is supported by flat-belt idlers or pulleys. To align a flat belt conveyor simply adjust the tail end pulley or the idler pulley, it is provided with adjuster bolt to adjust it in order to align the conveyor.

Side grip conveyors, also referred to as side belt conveyors, utilize parallel belts that grip product securely by the sides, enabling product to be conveyed while providing access to tops and bottoms. Product is held firmly in place during transfer across steep inclines. Industries such as the packaged-food and pharmaceutical industries, among many others, have benefited from these solutions.

A retractable conveyors are prized for their remarkable ability to enhance system flexibility. Retractable conveyors, also known as retracting conveyors and retractable tails, are conveyor frames that can retract, or extend, manually or pneumatically and typically on slides or rails. This function can happen infrequently with low accuracy or reoccur every few seconds with precision.

Loader-Unloader Conveyor unit for all application like for boxes, cartons, bags, etc. in warehouse, bottling plants, distilleries etc. and any places where material needs to be moved rapidly & efficiently. This conveyor is mostly reduce maximum labour & save time. These conveyor features are easy movability, slider bed design, zero maintenance.

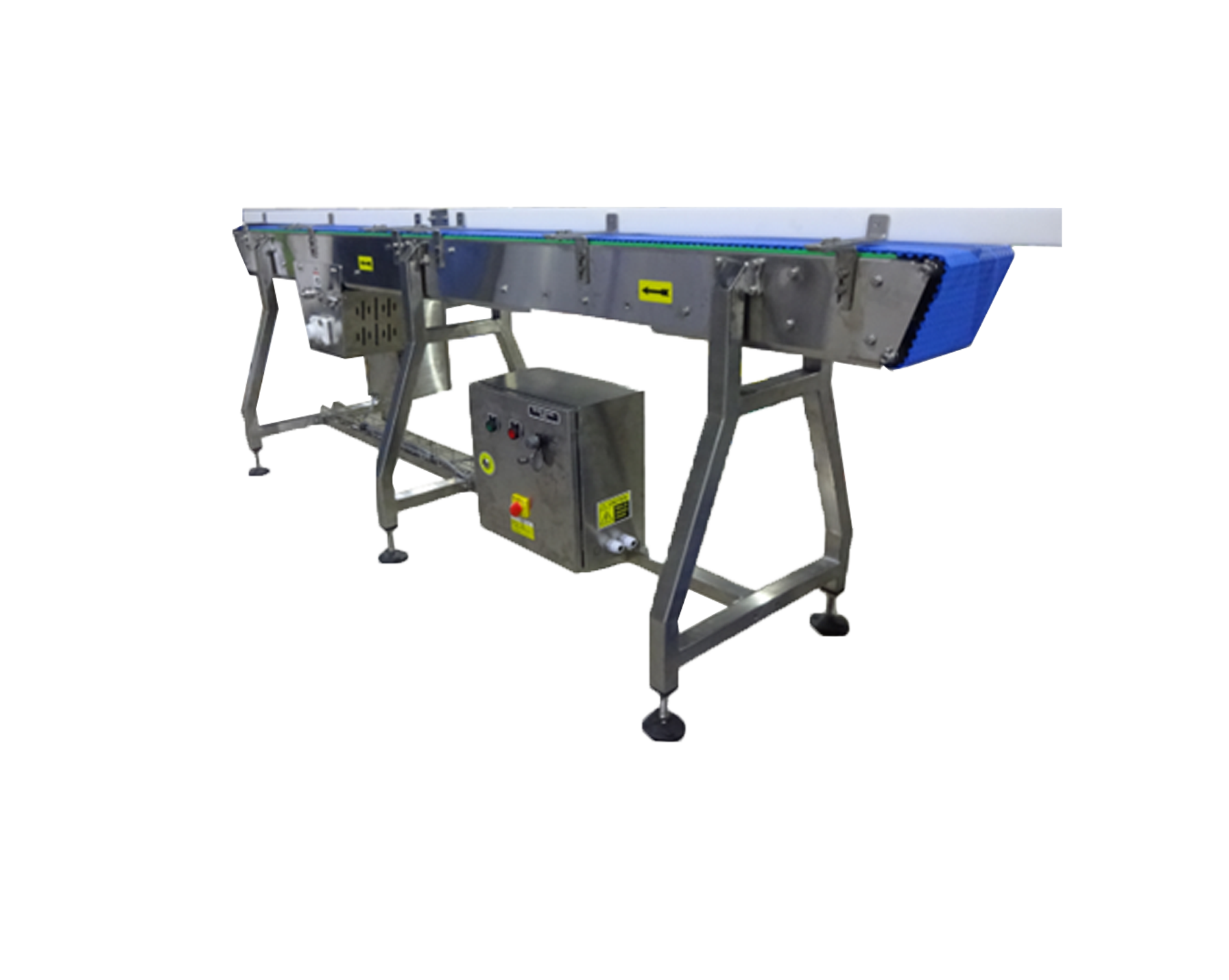

Food conveyors move foods and other organic materials through their processes safely and quickly. All at a fraction of the cost of manual labor the same task. The term “food conveyor” covers a wide variety of systems ranging from roller, belts and dumpers.

Cleated belt conveyors provide many purposes in today’s manufacturing environment. They are used to help move product up inclines, as well as stage product to operators or to provide predictable spacing on a line. With five standard conveyors that can have cleats attached to them, Safe Arabia is sure to have the right conveyor for your application.

Pallet conveyors transfer discrete products on carriers referred to as pallets typically transported by belt, roller chain, flat-top chain, or for extremely high loads, powered rollers

Screw conveyor is a kind of conveying machine that uses motor to drive spiral rotation to move materials to realize transportation. It is suitable for horizontal & vertical conveying of particles or powdered materials. It is a widely used in mineral, feed, grain and oil, construction industry.

In simple terms, bucket elevators vertically convey bulk materials. They are considered similar to conveyor belts, with the greatest difference being that bucket elevators move material using buckets attached to a rotating belt or chain. The buckets work to pick up material, move it to endpoint, discharge return to pick up a new load.

Trough Conveyors are designed to help keep loose or bulk materials in the center of the conveyor. The belt is troughed with rollers, rails, or with a slider bed that the belt conforms to. Trough belts are great for conveying loose or bulk materials, especially if the material is abrasive.

A bulk material conveyor is a machine or device designed to transport large quantities of loose materials. These types of conveyors can be found in factories, warehouses, and agricultural settings, where they are used to move items ranging from powdered chemicals to grains.