We are one of the most renowned names of the industry engaged in offering a wide range of high-quality Packaging equipment in the market. Our product range is made as per the exact demands of different industries and sectors. Moreover, we can customize the machines as per the specific demands of our esteemed clients. Our product range comprises Case packer, Liquid filling machines, Pallet strapping machine, Carton sealing machine, Cartoon erector, Palletizers

Packing Equipment

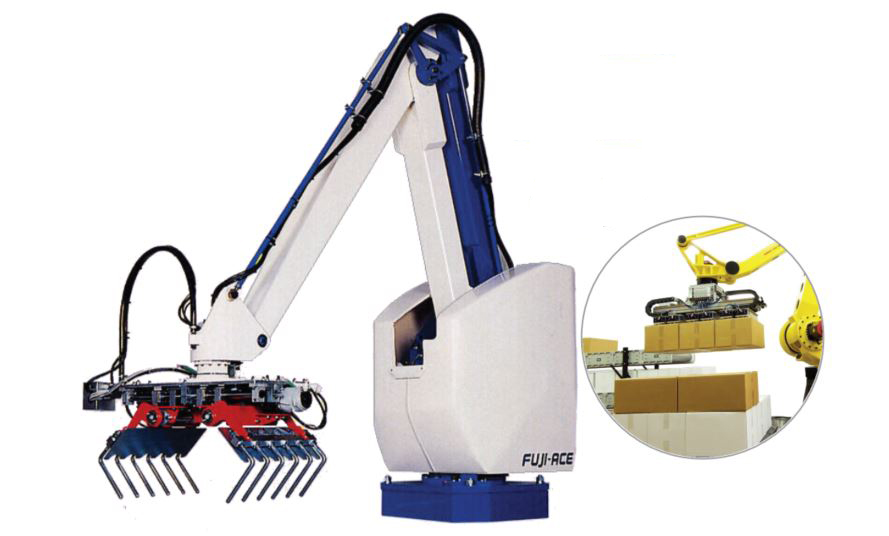

Depalletizing is the process of lifting on or off packages on a pallet. There is a wide selection of products that is today very much used when palletizing e.g. suction cups, large area vacuum gripper systems, or ergonomic handling systems in combination with vacuum pumps.

Transcedence Integrated Systems provides robotic case depalletizing solutions and robotic de-palletization for cased goods, bulk glass and cans, as well as specialty products such as bottle cans. Transcedence Integrated Systems has a range of fixed automation depalletizing systems ranging from semi-automatic models to high speed models with push button, recipe based change over. Multiple configurations allow for specifically designed functions such as dunnage sorting and distribution, multi-format product operation, and on-the fly change over.

Carton sealer, and Carton taping machine: Auto carton sealer is suitable for carton packing, which can be used for single use or production line. It adopts adhesive tape to seal carton, economy and fast, easy adjust. It can finish the sealing both top and bottom. Also you can adjust the height and width for different cartons. It widely used in home appliance, textile, food, general merchandise, medicine, chemical and so on.

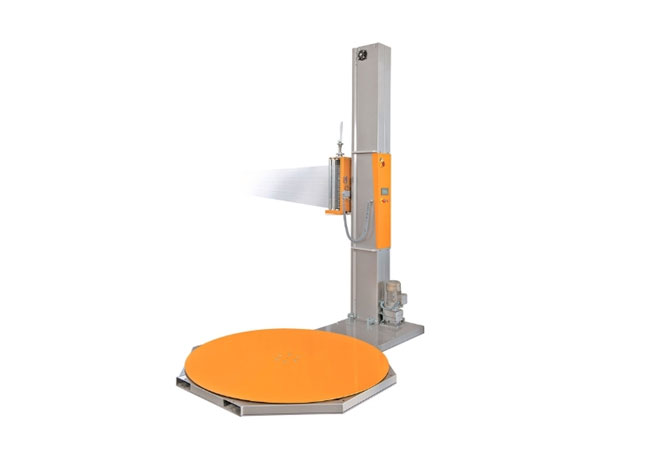

Pallet Stretch Wrapping Machine are designed to wrap stretch film around a loaded pallet. Film provides extra support while the products are being transported & storage to protect them from tip, spill or from being damaged. The wrapping type and times can be designed according to customers’ requirements.

Other Details:

- PLC

- Packing height controlled by limiting switch

- Top and up-down wrap times: 0-3 can be chosen

- Adjustable mechanical tension brake

- Power on/off switch and indicator

- Manual carriage up/down

- Variable turntable speed

- Carriage up/down speed control

- Manual/automatic exchangeable

Multi FleXL machine is designed to wrap large loads from 20 x 20 inches and up to 125 inches length x 66 inches width, with a maximum height of 120 inches. The machine is specially designed to wrap large loads like insulation bundles, sheets of drywall and corrugated boxes.

Key Features:

- The Multi FleXL is fitted with our patented film unwinding during stretch patent, which saves customers 10 percent in film consumption, is 100 percent waterproof, and eliminates the risk of contamination,

- The Multi FleXL can be configured with up to four different film sizes.

- The Multi FleXL can be set up to automatically switch between sizes to provide enhanced flexibility and a perfect fit for every load.

- Wrapping up to 150 loads an hour, depending on the size and height of the product, Multi FleXL further provides fast and accurate results.

A stretch wrap machine is a piece of equipment that automatically wraps pallets with stretch wrap. This keeps the products housed inside of the pallet contained and safe from damage.

Stretch film is wrapped tightly around packages or objects to secure them together or keep them protected. Whereas, shrink wrap, is applied by first covering the item loosely; then heat is used on the shrink wrap, causing it to recoil tightly around the package.

Materials. The most common stretch wrap material is linear low-density polyethylene (LLDPE), which is produced by copolymerization of ethylene with alpha-olefins, the most common of which are butene, hexene and octene.

The case packer is a robust machine that is versatile in case packing applications and easy to operate on the production floor. With capabilities to run lose products or bundled packs into RSC cases, trays or crates, the case packer is a case packer you simply cannot ignore.

Pick and place automation speeds up the process of picking up parts or items and placing them in other locations. Automating this process helps to increase production rates. Pick and place robots handle repetitive tasks while freeing up human workers to focus on more complex work

Using reliable automated case forming and sealing machinery can reduce your cost of tape and labor. Affordable case erection can be justified for forming as low as 500 cases per day. Hand taping will lead to unnecessary high tape usage which can be eliminated by using either random or uniform carton sealers. Case Sealer Equipment provides flexibility for your existing and future needs. Using reliable High-End automated case sealing machinery can reduce your cost of tape, time, and labor.

The benefits of wraparound case packing are numerous, such as flat blank storage and shipment and greater case blank magazine capacity. Typically, corrugate use is lowered and the cost per blank is less due to the unglued manufacturer’s joint. Improved palletizing can be achieved because the loaded Wrap Around cases are more square than a typical RSC type case.

Wrap Around case packers are designed with safety, durability, productivity and efficiency as the top design criteria. In addition, the Wrap Around case packer is capable of handling harness style case blanks, trays with or without display windows, and case blanks with tear-off perforations.

Shrink Wrap Machine wraps an item in a free sleeve or a loose polyolefin shrink film and heat is used to shrink the film tightly around. Shrink packing machines are very handy when a bulk of goods needs to be shrink-wrapped.

Do you need a reliable Print & Apply System that can handle dynamic data and apply labels quickly and accurately on any type of product?

NOVEXX Solutions Print & Apply Systems are designed to meet today’s high standards of product labelling and identification and to fulfil supply chain and logistics requirements. They are best suited for industrial environments, high and low product volumes, continuous operation, and a wide variety of label positions.

- Best print quality & precise application at high speed,

perfect for variable print data in real time - Maximum user-friendliness & highest quality standard

- Easy integration into any production line

- Ready for latest digital requirements

- Ribbon Save Function for more efficiency & sustainability

- Different print widths up to 160 mm – for labelling products, cartons and pallets

- Wide range of applicators to cover any labeling demand

By efficiently and consistently erecting boxes, automatic packing equipment can provide increased production and labor savings. A Combi case erecting machine gives you flexibility with easy changeovers and a range of speed capabilities.

Our case erectors also can be integrated with our case packers, providing a compact solution that loads products for shipping. At Combi, we engineer a variety of options and offer customizations to fit your needs.

At a basic level, a multi-head weigher takes bulk product and weighs it into smaller increments according to the weights programmed into its software. That bulk product is fed into the scale through the infeed funnel at the top, generally via an incline conveyor or a bucket elevator.

Each weigh hopper is equipped with a highly accurate load cell. This load cell will calculate the weight of product in the weigh hopper. The processor in the multihead Weigher will then calculate the best combination of available weights required to achieve the desired target weight.

FP 021 S is the result of our machines’ evolution and of many experience’s years in the field of horizontal products’ packaging. Electronic Horizontal Pillow Pack Wrapper, versatile and reliable, very flexible in the format-change, suitable for food and non-food products, both for single-dose and for multiple packages. Cantilever frame and easy accessibility, together with sanitation principles, easy maintenance and safety, it has been constructed for, allows this wrapper to distinguish itself.

The CERTOPAC, a fully automatic high-performance bagging machine, packs any type of free-flowing bulk material in pillow bags and gusset bags with a filling weight between 5 kg and 80 kg.

Thanks to its high speed, this open-mouth bagging machine can fill up to 1500 bags per hour. Because of the high flexibility of the packaging machine, bags made of woven PP, PE and paper can be processed. Furthermore, the CERTOPAC stands out due to its easy accessibility and high reliability.

Shelf Ready Packaging machines allow for more efficient replenishment at store level, which improves overall product availability and thereby results in greater product sales. Not only does SRP help businesses improve their sales, but it also provides businesses with more opportunities to display their products in a strategic manner. This allows businesses to make their products more noticeable in their store. Overall, using SRP leaves a smaller environmental footprint since corrugated cardboard is easily recyclable.

We offer some of the high-quality filling machines for diverse filling operations. Our product range includes viscous liquid filling machines along with the ones used for filling vials and bottles.

Liquid Filling Machine is a machine used in different industries for filling the raw material into the container and packing it making a finished product. This machine has benefited to various packaging company. In liquid filler, the tank, bottle or container moves in a cycle, gets filled by the machine and is further processed for packing.

Semi-automatic filling machines are ideal for small to medium scale production requirements. They offer fast, accurate and flexible filling solutions. Good operators can achieve output speeds of up to 40 containers per minute and changeover from one product to another takes only a few minutes. Most of the semi-automatic filling machines require only a compressed air supply. Semi-automatic filling machines are suitable for filling almost any liquid, from free flowing fragrances and alcohols, through to viscous syrups and adhesives and even liquids containing particles such as food products.

A robotic palletizer can handle one or more units at a time according to pallet configuration, and forms multiple layers on a pallet after picking the products off of a conveyor. Robotic palletizing solutions can easily accommodate different pallet patterns and product types.

Palletizer machines have become an essential part of automation, replacing human error and injury in manufacturing with efficiency and speed. In addition to such benefits, palletizers can handle environments that would otherwise be injurious to workers. Instead of requiring the hire of more laborers to do this work, many companies have adopted palletizers into their workplace environments in order to get the job done more quickly, effectively and safely.

Transcedence provides a packaging equipment solution for every application and budget. First, evaluate an application to help determine which style of machine is required. Then, select a carton sealing machine to improve productivity, reduce labor, reduce material usage and improve ergonomics.

Case sealers offer cost-cutting and consistent box sealing technology giving you the ability to manage the amount of tape used and the amount of time spent to seal a box. Every operator uses a different amount of tape to hand seal a box – tab lengths, additional passes, double strips, etc. – and the amount of time taken to open a box, seal the bottom, fill the box with product and void-fill, and top seal, can vary from box-to-box.

Strapping Machine is used to strap pack the carton boxes, newspapers, books, unitizing or bundling, thus makes it easier for carrying and transporting. We to provide wide array of standardized Strapping Machines for Pallets to our clients. The machine is ideally used for stretch film wrapping around the product and is highly known for reducing labor by automation of diverse processes such as attaching, detaching and pressing the film.